Inventory is always moving — you sell products, buy new ones, and the cycle repeats. Because stock ties up your capital, it is one of your riskiest investments. The key question is: how long does it take to sell what you have? Days of inventory on hand answers exactly that, telling you how many days your current stock will last before you need to reorder.

Days of Inventory (DSI) = (Average Inventory / COGS) × 365

Alternative: DSI = 365 / Inventory Turnover Ratio

Both give the same result. Use whichever data you have available.

In the professional term of economists, this indicator is called days of inventory. Using the results of your store, you can accurately calculate the number of days it will take to sell the entire batch of goods. The received number of days will give you answers to the following questions:

- When do I need to order the following products?

- How many days should I expect to service a batch of goods?

- How effective is my sales team?

- Do I have enough of this quantity of goods to satisfy the demand?

- Will I have enough goods for the next delivery?

Inventory on hand days may not seem like an important indicator, but it can show you the effectiveness of two aspects of your business - inventory management and the sales capacity of your store. You will be able to:

- Maintain the correct balance of stocks

- Meet the needs of customers without losses

- Avoid the situation of excess or shortage of stocks

- Reduce the risk of crisis

- Ensure stable sales

This will happen if you take this indicator into account when planning your business and purchasing goods.

In this article, we'll look at how to calculate days on hand. You'll see the main formulas with simple explanations and examples. We'll also cover what to do if the results don't look good and how Mipler can help with the calculations.

What are inventory days?

Let's consider a more precise definition of the indicator:

Days of inventory is a financial ratio that indicates the average number of days it takes a company to sell all of its inventory.

This indicator is used to determine the effectiveness of inventory management and evaluate your ability to convert inventory into sales. In general, this is another way to determine business efficiency.

In the classic economic literature and in other articles on the Internet, you may find that inventory days can be called in different ways. The most common names are days sales of inventory (DSI), average age of inventory, inventory on hand days, days inventory outstanding (DIO), days in inventory (DII), or days sold in inventory. Unless some additional explanations are given, then usually, this is one and the same concept. The difference can be only in the method of calculating this indicator.

Given the name of this ratio, it is clear that it is part of inventory management. It is not mandatory. However, it is worth paying attention to it if there are problems with the delivery or production of products. If you do not have enough time for production, or there is a surplus that you could not sell. True, you do not have to calculate the inventory days if you are satisfied with the results of your store.

In general, the main purpose of the indicator is to show how many days you will need to prepare new supplies. But apart from that, you will also be able to get information about solving some other problems. For example:

- Procurement management and budget planning are the first problems solved by correctly understanding and using the indicator.

- Secondly, if you calculate inventory days separately for each type of product, you can immediately see the difference in their popularity and demand

- Thirdly, the value of this indicator indicates the results of your sales activities

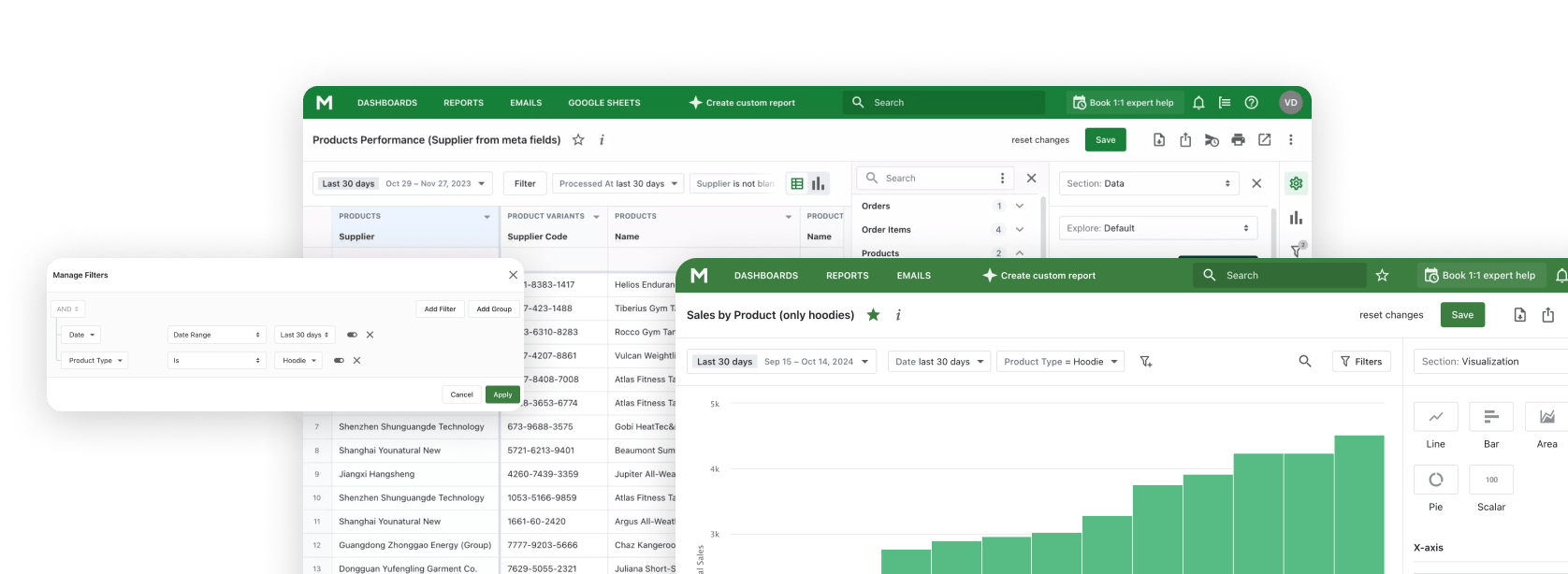

Explore related reports

Formulas definition

Managing inventory is all about balance. Too many stock ties up money, while too little leads to lost sales. To keep control, businesses use a few simple formulas to measure how long products stay in inventory. Below, we have listed our most common formulas, which we'll explain in this article.

1. Days Sales of Inventory (DSI)

DSI = Average Inventory / COGS * Days in Period

We use DSI to show how many days, on average, it takes to sell all the inventory you have.

Example:

- Average Inventory = $250,000

- Annual COGS = $1,825,000

250,000 / (1,825,000 / 365) = 50 days

This means it takes about 50 days to sell your stock. If you want to avoid running out, you should plan reorders around day 40.

2. Average Inventory

Store owners use it to represent the typical inventory you hold during a period. This number is often used in other formulas.

Average Inventory = (Beginning Inventory + Ending Inventory) / 2

Example:

- Beginning Inventory = $200,000

- Ending Inventory = $300,000

(200,000 + 300,000) / 2 = 250,000

By using this calculation, on average, you kept $250,000 worth of inventory during the year.

3. Inventory Turnover Ratio (ITR)

ITR shows how many times you sold and replaced your inventory within a period. Higher is usually better — it means products sell quickly.

ITR = COGS / Average Inventory

Example:

- COGS = $1,825,000

- Average Inventory = $250,000

1,825,000 / 250,000 = 7.3

By applying this formula, we sum up that your inventory rotates about 7.3 times per year.

4. Days in Inventory (via Turnover)

We also have another way to measure how long inventory stays in stock, but using turnover speed.

Days in Inventory = 365 / ITR

Example:

- ITR = 7.3

365 / 7.3 ≈ 50 days

By applying a different approach, on average, your stock stays in inventory for 50 days, which matches the DSI calculation.

These formulas help you understand how quickly products move, when to reorder, and how efficiently you manage stock. Used together, they give a clear picture of your inventory health.

5. Calculate in Excel or Google Sheets

If you track inventory in a spreadsheet, you can calculate days of inventory directly with this formula:

=AVERAGE(B2, B3) / B4 * 365

Where B2 = Beginning Inventory, B3 = Ending Inventory, and B4 = COGS for the period. This gives you DSI automatically as you update your data each month or quarter.

How do you calculate inventory days?

Two ways can be used to evaluate a day's inventory. Your choice depends on how you view the day's inventory and what data you are more comfortable using. We will get the same result; we will just look at inventory and inventory days differently.

The first method offers a seller's view - how many days will it take you to sell an entire lot of stock? The second shows the warehouse manager's point of view - what the stock turnover is and how many days they are in the warehouse. This method should be used depending on which approach is closer to you.

Days sales of inventory formula (DSI)

The first way to calculate inventory days on hand is called Days Sales of Inventory (DSI). It uses the cost of inventory and the cost of goods sold. This method works well if you measure results by sales, because the data is already available. It shows how many days, on average, it will take to sell your stock. The formula is below.

DSI=(Average inventory/COGS)*Days in accounting period

Let's see an example. Here are your results for the year: average inventory $250,000, cost of sales $1,825,000. Your formula will look like this:

250,000 / (1,825,000 / 365) = 50 days of inventory on hand

And after this simple manipulation you know that for the next year every 50 days you will have new products. Based on the received data, you need to place an order with suppliers on the 40th day, because the delivery takes 9 days. + you can plan the cleaning of the warehouse for day 49, because the warehouse will be almost empty in the evening of this day. The example is conditional, but the logic is approximately as follows.

In the example we use 365 days because we are calculating the DSI for a full year. You can also use 90 days for a quarter or 30 days for a month — the choice depends on the specifics of your business.

Average inventory calculation

Average inventory is the cost of your inventory. To calculate it, you can use one of two formulas:

Average Inventory=Ending Inventory

or

Average Inventory=(Beginning Inventory+Ending Inventory)/2

Formulas are selected depending on the accounting method. If you check inventory days only at the end of the period, then take the first method, if during the entire reporting period, then the second formula will provide you with accurate data, and not the first.

! Remember that the Average Inventory includes all categories of inventory: finished products, work in progress, raw materials, and current payments.

Inventory turnover method (Inventory turnover ratio)

In the end, we got to the second method. In some ways, it is simpler than the first. But only if you have the necessary information.

This point of view suggests looking not at sales results, but at the speed of updating the assortment in the warehouse. To put it simply, we will find out how long the stock remains in stock. Only one variable is used for the calculation - inventory turnover.

ITR=(1/inventory turnover) * 365

Example (same as above): You are a warehouse manager and you mentioned that you purchase new products approximately 7.3 times a year. Then you just need to divide 365 by 7.3 and you will get a result of 50. This means that every 50 days you buy goods again.

For reference: inventory turnover equals COGS / Average Inventory. If you already know how many times per year you restock, the turnover method is the simplest way to get your days of inventory.

Days sales of inventory ratio formula = Inventory turnover method

As we said earlier, inventory days on hand can be calculated in two ways, but you will get the same result. This can also be seen in the example we gave. From a mathematical point of view, equality will look like this:

(Average inventory/COGS) * 365 = (1/inventory turnover) * 365

The comparison looks very interesting, because you can immediately notice that DSI and inventory turnover are almost opposite concepts. It is only necessary to multiply the inverse value of inventory turnover by the period for which we are checking. This is the main idea - to give an opportunity to solve the problem in two ways, to approach it from two sides.

Tips for calculating inventory days

In addition to providing you with the tool, we would also like to help evaluate the results of using it. Here are some tips on how to calculate and use inventory days on hand:

- Use the method that is more convenient for you. It is better to use the data that is available than to make a mistake in calculating new indicators for you.

- Make calculations with the first periodicity, for example, once a quarter, to keep your hand on the pulse. For the good operation of the store, the number of days during which stocks remain in stocks should be as small as possible. Then this indicates that the efficiency of inventory and sales management is high. It is in order to avoid unpleasant surprises that you should constantly check the results.

- Consider seasonality to avoid running out of stock. For example, before the holidays you may want to increase inventory to prepare for higher sales, which makes this indicator especially important. On the other hand, after the season ends, the indicator may rise above the normal range, showing that products are staying in the warehouse longer

- Cross-functional collaboration - work closely with sales, procurement and finance to gather comprehensive data and analytics.

How to reduce days of inventory

A high DSI means your capital is sitting on shelves instead of generating revenue. Here are proven strategies to reduce your days of inventory and improve cash flow:

Improve demand forecasting

Use historical sales data to predict what you'll sell next month or quarter. If you run a Shopify store, tools like inventory reports let you see sell-through rates by product and variant, so you order what actually sells — not what you think will sell.

Negotiate shorter lead times

Shorter lead times mean you can order smaller batches more often. This directly reduces the average inventory you hold and lowers DSI. Work with suppliers on faster shipping, or consider domestic sourcing for your fastest-moving SKUs.

Run promotions on slow-moving stock

Identify products with above-average days on hand and create targeted discounts, bundles, or flash sales. Use ABC analysis to separate high-value items (worth protecting) from C-items (worth discounting aggressively).

Set automated reorder points

Instead of reordering manually when stock "looks low", set reorder points based on your lead time and average daily sales. This prevents both overstocking and stockouts, keeping your DSI in the optimal range.

Review your inventory valuation method

Your inventory valuation method (FIFO, LIFO, or weighted average) affects how COGS is calculated, which directly impacts your DSI number. Make sure your method reflects your actual product flow.

What is a good days of inventory ratio?

There is no universal "good" number — the ideal days of inventory depends on your industry, product type, and supply chain. However, these benchmarks can help you evaluate where you stand:

Industry |

Typical DSI Range |

Notes |

Grocery / perishables |

2 – 10 days |

Short shelf life demands rapid turnover |

Fashion / apparel |

30 – 60 days |

Seasonal collections drive variation |

General ecommerce |

20 – 50 days |

Depends on product mix and fulfillment model |

Electronics |

30 – 60 days |

Rapid depreciation makes low DSI critical |

Manufacturing / heavy goods |

50 – 100+ days |

Long production cycles increase holding time |

A useful rule of thumb: your optimal DSI should roughly equal your lead time plus safety stock days. If your supplier delivers in 14 days and you keep 7 days of safety stock, aim for a DSI around 21 days. Anything significantly above that may indicate overstocking.

Always compare your DSI against businesses in your own niche, not across industries. A 45-day DSI is excellent for furniture but problematic for fresh food. Seasonality also matters — expect higher DSI before peak seasons (holiday stock builds) and lower DSI afterward.

Days of inventory for ecommerce and Shopify stores

Ecommerce businesses face unique inventory challenges that differ from brick-and-mortar retail. When calculating days of inventory for ecommerce, keep these Shopify-specific factors in mind:

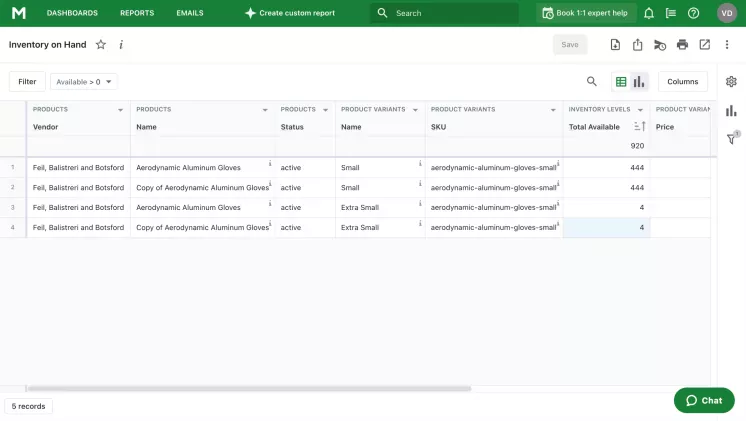

Multi-location inventory

If you use Shopify's multi-location feature or fulfillment centers (3PL), your inventory is split across warehouses. Calculate DSI per location to identify which warehouses hold too much stock and which need replenishing. A single average can mask imbalances.

Variant-level tracking

A product may have a healthy overall DSI, but individual variants (sizes, colors) can vary wildly. Size XS might have 120 days of inventory while size M has only 8. Shopify stores should track DSI at the variant level to make smarter purchasing decisions.

Seasonal and promotional spikes

Ecommerce sales are heavily influenced by promotions (Black Friday, flash sales) and seasonal patterns. Your COGS during a promotional month may be 3× the normal rate. Use rolling averages (3-month or 6-month) instead of annual figures to get a more accurate picture of your current inventory velocity.

Typical DSI for online stores

Most Shopify and ecommerce stores operate with a DSI between 20 and 50 days. Dropshipping stores can operate near zero since they don't hold inventory. Print-on-demand is similar. But if you hold your own stock, aim for a DSI that matches your reorder lead time plus 5–10 days of safety stock.

Use Mipler Inventory Reports to automatically calculate days of inventory per product, variant, and location directly from your Shopify data — no spreadsheets required.

Days of inventory calculator

Enter your numbers below to instantly calculate your days of inventory on hand. You can use either the DSI method (if you know your inventory and COGS) or the Turnover method (if you already know how many times per year you restock).

Your Days of Inventory on Hand:

Average Inventory: $ ÷ COGS: $ × days

How can Mipler help you calculate days of inventory?

Mipler offers advanced inventory management solutions that simplify the calculation of inventory days. With features like real-time data tracking and automated reporting, Mipler helps businesses. We can help you with your calculations in the following ways:

- We will provide accurate and organized data for calculations with the help of Shopify Inventory Reports.

- We can make a custom column that will calculate the value of inventory days on hand for you.

- We can prepare a separate Shopify Report in which all variables and the results of calculations with them will be displayed.

You may also find these related resources helpful:

- Shopify Inventory Reports — a complete overview of all available inventory reports

- Important KPIs for Inventory Management — key metrics beyond days of inventory

- Inventory Valuation Methods — understand FIFO, LIFO, and weighted average

- ABC Inventory Analysis Guide — prioritize products by revenue contribution

Try Mipler — the #1 Shopify reporting app. Start your free trial today.

Frequently asked questions about inventory days

What does days in inventory measure?

Days in inventory (DSI) shows how long, on average, it takes a company to sell its current stock. It reflects how well the company manages its inventory and turns it into sales. A lower number typically means faster turnover and better cash flow.

How to calculate inventory days on hand?

You can calculate it in two ways:

- DSI method: (Average Inventory ÷ COGS) × Days in the period

- Turnover method: 365 ÷ Inventory Turnover Ratio

Both formulas give the same result, so use whichever data you have available.

What is a good days of inventory ratio?

It depends on your industry. Grocery stores typically aim for 2–10 days, fashion and apparel for 30–60 days, and general ecommerce for 20–50 days. A useful benchmark: your optimal DSI should equal your lead time plus safety stock days.

What is the average number of days on hand?

The average number of days on hand indicates the typical duration that inventory is held before it is sold. This metric provides insight into inventory turnover rates and helps businesses maintain optimal stock levels.

Is DIO the same as DSI?

Yes. Days Inventory Outstanding (DIO), Days Sales of Inventory (DSI), Days in Inventory (DII), and Days on Hand (DOH) all refer to the same concept — the average number of days it takes to sell your inventory. The difference is usually just the naming convention.

Should I use 365 or 360 days in the formula?

Use 365 for annual calculations and 90 for quarterly. Some analysts use 360 for simplicity, but what matters most is consistency — pick one and stick with it across all your calculations so you can compare periods accurately.

How can I reduce my days of inventory?

Common strategies include: improving demand forecasting, negotiating shorter lead times with suppliers, running promotions on slow-moving stock, implementing ABC analysis to prioritize high-value items, and using automated reorder points. Regularly tracking DSI helps you spot issues before they become costly.

What is a normal days of inventory for ecommerce?

Most ecommerce and Shopify stores operate between 20 and 50 days of inventory. Dropshipping and print-on-demand businesses can be near zero. Your target DSI should match your supplier lead time plus 5–10 days of safety stock.

How do I calculate days of inventory in Shopify?

Shopify doesn't have a built-in DSI report, but you can export your inventory and sales data, then apply the formula (Average Inventory ÷ COGS) × 365. For automated tracking, use Mipler Inventory Reports to calculate DSI per product and variant directly from your Shopify data.